Supply chain resiliency has become a prominent topic of discussion in the wake of the COVID-19 pandemic, and its significance remains high due to various ongoing global issues. To understand resilience, we can define it as the capacity to endure or recover swiftly from challenges. When applied to the supply chain context, resilience can encompass different aspects, leading to varying interpretations.

For some, it involves nearshoring and mitigating risks associated with geopolitical dynamics that constantly evolve. Others focus on addressing operational challenges related to workforce availability and timely access to raw materials through capacity and inventory buffers. Given the diverse areas that need attention, it is crucial to adopt a holistic approach when approaching supply chain resilience. Conducting comprehensive audits can help identify inherent strengths, weaknesses, and areas that require improvement.

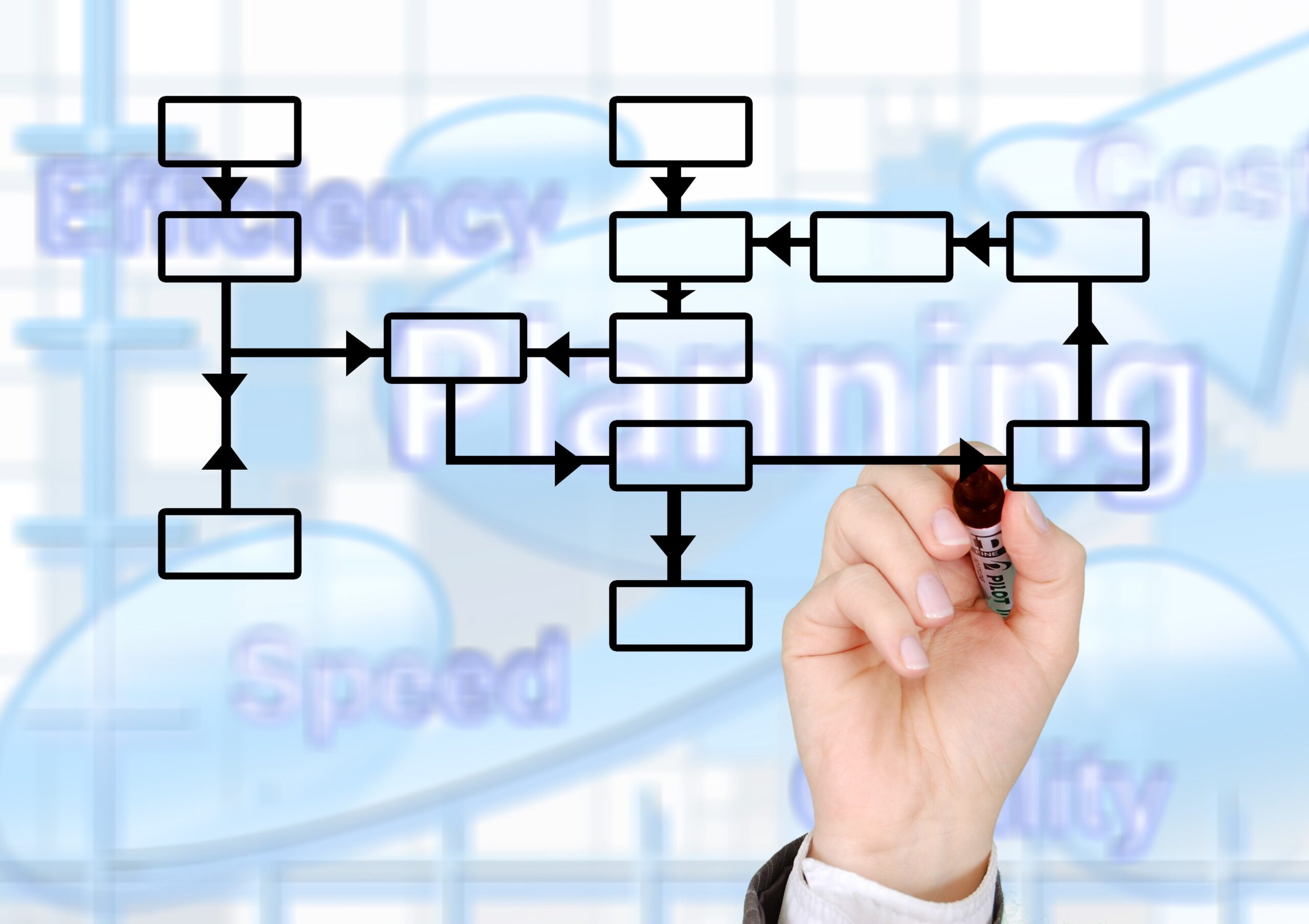

In most cases, the measurement of supply chain resilience revolves around its ability to meet demand promptly. It is important to acknowledge that supply chains exist because of the demand they serve. Therefore, any discussion on resilience should begin by considering the demand disruptions and the organization’s capability to meet it through timely supply. Neglecting this aspect can have severe consequences for businesses, potentially eroding profitability entirely. Now, let’s delve into the different types of disruptions that can upset the delicate balance between demand and supply:

Image 1: Supply Chain Disruptors

Demand Disruptors

- Competition: Intense competition within the market can lead to shifts in customer preferences and demand patterns, affecting the equilibrium between supply and demand.

- Local Events & Weather: Natural disasters, political unrest, community events, or extreme weather conditions can disrupt demand by impacting local economies and consumer behavior.

- Macro Economic Fluctuations: Economic fluctuations, such as recessions or inflation, can influence consumer purchasing power and consequently impact the demand for products and services.

- Climate Impact: Environmental factors, such as climate change-induced disruptions, can alter demand patterns by affecting agricultural production, transportation networks, and consumer behavior.

- Changing Trends: Evolving consumer trends and preferences can quickly shift demand away from certain products or services, requiring supply chains to adapt accordingly.

- Customer Behavior: Changes in consumer behavior, such as shifting preferences for online shopping or demand for sustainable products, can disrupt traditional supply chain dynamics.

- Technology Revolution: Rapid advancements in technology can introduce new products or disrupt existing industries, impacting demand and requiring supply chains to adapt to new market conditions.

- Ad hoc Merchandise Plans: Abrupt or ad hoc plans related to bulk buying, new product introductions, pricing, and promotions can heavily impact the supply chain by constraining capacities and creating challenges in positioning inventory in a timely manner.

Operations Disruptors

- Material Shortage: Shortages or disruptions in the availability of raw materials or components can interrupt production and affect the ability to meet demand.

- Manpower Challenges: Inadequate staffing levels, whether due to labor market conditions, health crises, or other factors, can hinder operations and impact the ability to fulfill demand.

- Capacity Constraints: Insufficient capacity in terms of facilities, equipment, or logistics infrastructure can limit production capabilities and delay supply chain responsiveness.

- Equipment or Logistics Breakdown: Unexpected breakdowns or failures of critical machinery or transportation can disrupt operations, resulting in downtime, delayed production, and potential disruptions in meeting demand.

- Quality Issues: Quality control problems, such as product recalls or supply of substandard components, can result in disruptions to supply chains and damage customer trust and demand.

- Inventory Obsolescence: Holding excessive or outdated inventory can lead to obsolescence, rendering the inventory unusable or less valuable over time. This can tie up capital and create inefficiencies in meeting demand.

- Inventory Shrink: Inventory shrink due to misplacement, theft, wastage, damage, or other factors can disrupt the production and distribution planning process, leading to inaccuracies in inventory levels and potentially impacting the ability to fulfill demand.

Supply Disruptors

- Geo Political Issues: Political instability, trade disputes, sanctions, or changes in government policies can disrupt global supply chains by impeding the flow of goods and materials.

- Environmental Disasters: Natural disasters, such as earthquakes, hurricanes, or floods, can damage infrastructure, disrupt transportation networks, and impact the availability of goods and services.

- Compliance Issues: Non-compliance with regulatory requirements or challenges related to environmental, social, and governance (ESG) standards can disrupt supply chains and impact the ability to meet demand.

- Operational: Operational issues, including breakdowns in machinery or transportation, congestions at ports, or variations in lead times, can hinder the smooth flow of goods and cause disruptions in supply.

- Inflation & Energy Prices: Fluctuations in inflation rates or energy prices can impact production costs, transportation expenses, and ultimately affect the ability to supply products at competitive prices.

- Financial Instability: Financial instability, such as liquidity issues, bankruptcy, or credit constraints, can disrupt supply chains by impeding access to capital and hindering operations.

- Pandemics: Outbreaks of infectious diseases, such as the COVID-19 pandemic, can severely disrupt supply chains by causing labor shortages, restrictions on movement and trade, factory shutdowns, and disruptions in transportation networks.

By understanding these various disruptions, supply chain stakeholders can develop strategies to enhance resilience and mitigate the impact of potential disruptions on the delicate balance between supply and demand.

Creating a resilient supply chain requires a focused approach across structural aspects, systems and process maturity, sense and respond capabilities, and synergistic orchestration. Let’s explore some key elements across these four areas:

Image 2: 4 S of Supply Chain Resilience

Structural Design

Product Design:

- Complexity of design: Simplifying product design complexity to streamline manufacturing and sourcing processes.

- Components/raw materials and supply sources: Assessing and diversifying the sources of components/raw materials to mitigate supply chain risks.

- Standardization of parts across the portfolio: Implementing standardized parts across product lines to enhance flexibility and reduce dependency on specific suppliers.

- Delayed product differentiation: Deferring customization or differentiation of products until later stages of the supply chain to improve responsiveness.

Network Design:

- Sourcing strategy — domestic vs. international: Evaluating the trade-offs between domestic and international sourcing to optimize cost, lead times, and supply chain resilience.

- Diversified supplier/manufacturing partners: Establishing partnerships with multiple suppliers and manufacturers to minimize disruptions and enhance flexibility.

- Flexible network: Designing a network that can adapt to changing market conditions and accommodate fluctuations in demand and supply.

- Capacity redundancies: Building redundancy and backup capacity in critical areas of the supply chain to mitigate disruptions.

Systems & Process Maturity

Real time systems:

- Real-time capabilities: Implementing systems that enable real-time data synchronization and processing to facilitate on-time decision-making aligned with the current reality.

Flexible Systems:

- Adjustable parameters for production, distribution & inventory management: Designing systems with adjustable parameters that allow for dynamic production, distribution, and inventory management, such as flexible flow paths, schedules and buffers.

- Amendable plans & orders: Implementing systems that can accommodate changes and updates to production plans and orders in real-time.

- Adaptive multivariate long/mid-term demand forecasts: Utilizing AI forecasting models to predict long and mid-term demand patterns considering multiple intrinsic and extrinsic variables.

- Demand sensing and demand shaping : Implementing demand sensing capabilities, inventory optimization techniques and strategies to align inventory levels with demand while also shaping demand through promotions or incentives.

Automated and connected processes:

- Production and warehouse process automation: Introducing automation technologies to streamline operations, increase efficiency, and reduce human errors.

- Connected devices, equipment, and products: Leveraging the Internet of Things (IoT) to enable real-time monitoring, data collection, and communication across the supply chain.

- Business process workflow automation: Automating manual workflows and tasks to improve operational efficiency and reduce lead times.

- Empowering frontline workers with digitized operations: Equipping employees with digital tools and technologies to enhance their productivity and decision-making capabilities.

Sense & Respond Capabilities

End-to-End Visibility:

- N-tier supplier visibility: Gaining real time visibility into suppliers’ financial health, compliance with regulations, and adherence to environmental, social, and governance (ESG) standards.

- Extrinsic factors: Monitoring external factors that could impact the supply chain, such as events, weather conditions, and environmental disruptions.

- Partner production plan, inventory, capacity: Sharing and accessing production plans, inventory levels, and capacity information with partners in the supply chain.

- Demand plan, inventory, order & shipment visibility: Obtaining visibility into demand forecasts, inventory levels, order status, and shipment tracking throughout the supply chain.

- Operations visibility — Multi-modal logistics, Facilities: Gaining visibility into multi-modal logistics operations and the status of facilities to ensure efficient and timely execution.

Data-Driven Transformation:

- Digital twins, advanced analytics & AI: Leveraging technologies like digital twins, advanced analytics, and artificial intelligence to gain insights, identify patterns, and optimize decision-making.

- Predictive capabilities: Using predictive capabilities to forecast inventory levels, lead times, and price fluctuations to make informed supply & demand planning decisions.

- Alert-driven event management: Setting up alert systems that notify stakeholders about critical events or disruptions, enabling rapid response and proactive management.

- Scenario simulations: Conducting scenario simulations to evaluate the impact of different scenarios on the supply chain network and facility operations.

- Next best action recommendation: Utilizing data-driven insights to provide recommendations on the best course of action in response to disruptions or changing conditions.

Synergistic Orchestration

Collaborative Design & Planning:

- Cross-functional product design process: Facilitating collaboration and communication between different functions involved in product design to optimize for manufacturability, cost, supply chain and sustainability.

- Integrated merchandise planning, supply planning & operational planning: Aligning merchandise planning, supply planning, and operational planning to ensure a synchronized approach across the supply chain.

- Bi-directional data sharing with partner network & collaborative planning: Establishing data-sharing mechanisms and collaborative planning processes with partners in the supply chain to enhance visibility and coordination.

Seamless Product Flow Execution:

- Real-time visibility-enabled seamless operations planning and execution: Leveraging real-time visibility and data to enable smooth operations planning and execution, minimizing delays and disruptions.

By focusing on these elements, supply chain practitioners can enhance the resilience of their supply chains, adapt to disruptions more effectively, and ensure the continuity of operations even in challenging circumstances.