The term “control tower” in the supply chain space has always puzzled me as it implies a level of control that is often not achievable once operations are in motion. Therefore, a more accurate term might be “Supply Chain Intelligence Tower”. However, despite this misnomer, I have come to realize that each organization has a unique perspective on what the term means, which also varies depending on the unit or department. For example, there are planning control towers, operational control towers, transportation control towers, and so on. Nevertheless, everyone agrees on the foundational aspect of the control tower, which is end-to-end visibility on plans and operations, and intelligence derived from it. Defining the scope of the control tower – whether it is for a function, department, or end-to-end supply chain – should be prioritized based on complexity and the potential value it can deliver.

What is a Supply Chain Control / Intelligence Tower?

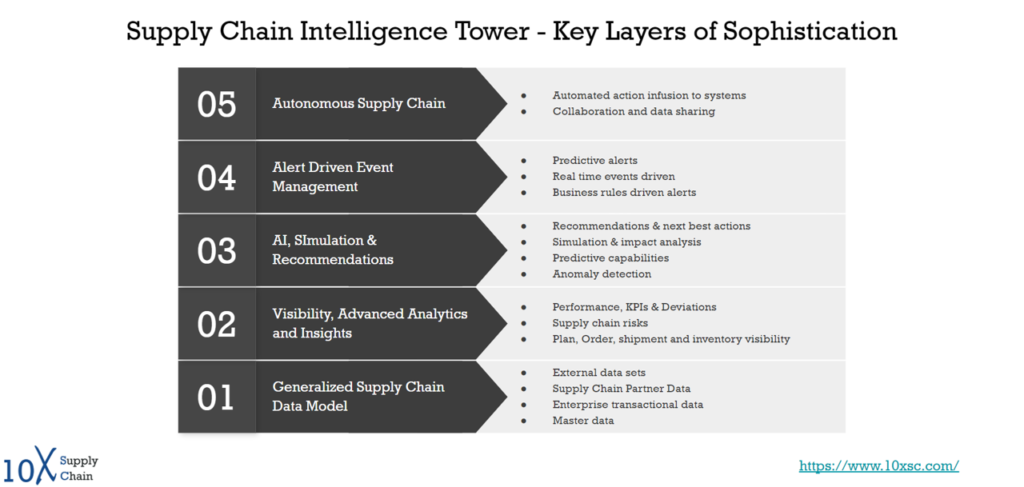

A supply chain intelligence tower typically comprises multiple layers of sophistication. The foundation of the tower is the data layer, which brings together data from enterprise systems, partner systems, and external data providers. The subsequent layers focus on using this data to drive advanced analytics, develop specific use cases with the help of AI, and understand the impact of scenarios through simulations. At the minimum level, the tower should provide an alert-driven event management system to quickly act on insights. At the highest level of sophistication, the supply chain becomes autonomous, enabling automatic execution of actions or recommendations within the systems.

Image 1: Supply Chain Control / Intelligence Tower – Representative Layers

However, organizations often struggle to articulate the value of a control tower and become overly concerned with the complexities of data collection. Additionally, determining ownership of the control tower, especially if it is envisioned as an end-to-end solution, can create confusion and hinder progress. To address these issues, it is crucial to first define the scope of the control tower and define clear business ownership. One of the large retail chains, had created a new cross functional team involving stakeholders from procurement to inventory to logistics operations to operationalize the insights and interconnected action recommendations.

Path to Realization

Once an organization overcomes its initial doubts about implementing a supply chain control tower, one of the major queries is whether to build it in-house or buy an existing solution from an application provider already present in the enterprise systems landscape. While these players are able to conceptualize and demonstrate control towers with fancy screens showing alerts and recommendations, the realization of a control tower solution is more of a data-driven transformation journey than a typical application in the systems landscape that can be simply plugged in and configured. Regardless of whether one chooses an off-the-shelf solution or bespoke, a significant amount of data must be collected from various sources.

Another crucial aspect to consider is the scope of the control tower. Typically, off-the-shelf solutions in the application landscape focus on a specific area, such as planning or logistics. However, to derive continued and incremental benefits from a supply chain intelligence tower, an organization must decouple data from applications to create a unified and interconnected data platform that allows the entire supply chain to be viewed in one place. This data-driven transformation journey requires significant investment and expertise, but the benefits are immense. By creating a digital representation of the physical supply chain, organizations can gain end-to-end visibility and make more informed decisions, leading to increased efficiency, cost savings, and a competitive advantage.

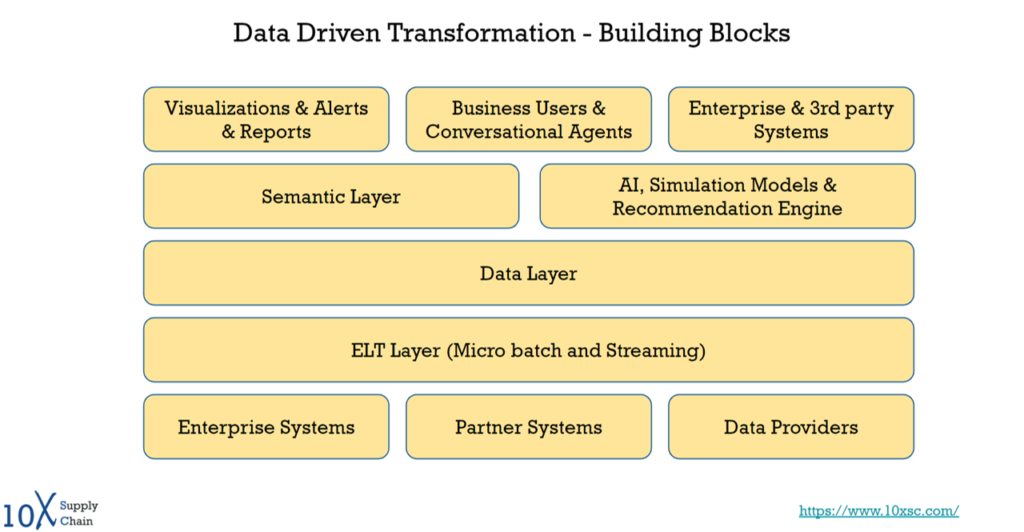

To decipher the data driven transformation journey, it’s essential to examine its building blocks. One of the most challenging aspects of this journey is collecting data from various sources and harmonizing it in the data layer, especially in organizations that have grown inorganically through acquisitions or with multiple partners in the ecosystem. The collection of data has evolved from traditional ETL to ELT, and now schema-aware data exchanges or zero ETL. Some organizations have a separate data and analytics strategy. For example, one large household appliance company attempted to derive value from their data by dumping it all into a data warehouse first and then determining the use cases to be built. Unfortunately, this approach resulted in a very long time to derive any meaningful value from the data. This also creates complexity in defining a business consumption-ready data model. While it’s complex to define a data model that can hold the data across functions, there are certain aspects of the data that cut across the organization, and there are others that are specific to each function. So, a balanced approach in defining a common model and then additions based on the areas of focus. Some leading BI tools offer sophisticated semantic layers that can standardize measurements, KPIs, and data governance, creating a consumption layer that’s common across consumers, whether it’s a visualization or an API to expose some of the metrics. Advanced AI tools with foundational models can then be used to harness this data quickly. The insights, predictions, and recommendations hence derived need to be actioned, either through manual intervention using an alert driven event management or autonomous execution in the systems through an integrated approach.

Image 2: Data & Analytics Transformation Building Blocks

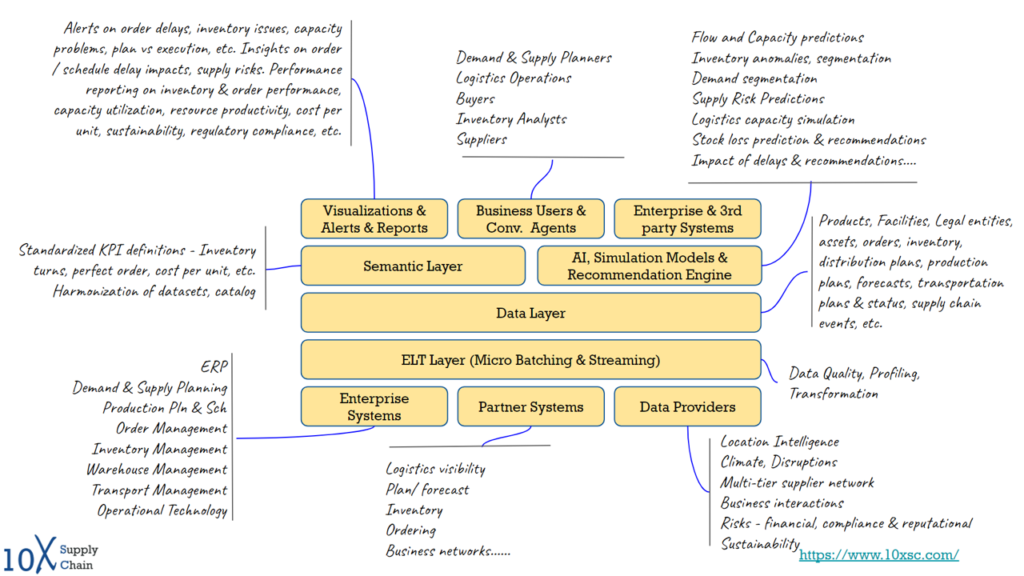

Now let us look at how these building blocks would look in supply chain specific context, with some examples to give a flavor of this data driven journey.

Image 3: Supply Chain Intelligence Tower – A data driven transformation

Recipe for Success

- Create a cross functional team by breaking down the silos and collaboratively define the objective for the supply chain intelligence tower.

- Align this with the organization’s data and analytics journey. Having a separate stream for supply chain control / intelligence tower would be a prolonged program with potential cost overruns and duplicated efforts.

- Evaluate where the organization is in its data driven transformation journey, identify how supply chain control tower initiative is aligned with the overarching objective,

- Create a prioritized roadmap for quick wins, medium term and long term iterations, based on the data availability, complexity of the use case and potential for value delivery.

- A collaborative way of working with supply chain business teams and the data teams delivering the use cases in an iterative manner.

- Tools and technology matter in making this journey faster and easier, and fortunately there are many to choose from.